Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material.

Calculate angle to form sheet metal.

Punch edge radius in.

By doing so the sheet can be bent or stretched into a variety of complex shapes.

With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements.

Typical acute angle tooling profiles are 30 45 and 60 though there is custom tooling and air bending allows for the forming of any angle larger than the angle of the punch tip.

Punching force calculation formula.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

Straight angle a geometry term for an angle which is equal to 180.

Ultimate tensile strength psi.

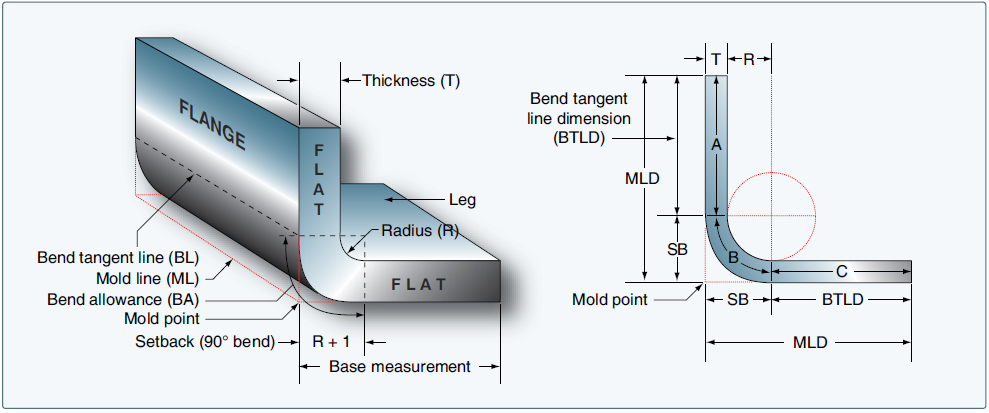

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

You only have to insert interior angle flange lengths k factor inside radius and material thickness.

R is inner bend radius.

If you punch round holes or square holes or some other forms of holes through a given thickness of metal you just want to know the force required to punch a hole in steel.

Bends in sheet metal are manufactured using sheet metal brakes.

As this happens you gain a small amount of total length in your part.

Bend angle represents the angle to which sheet metal has bend here it is 90 degree.

Tooling general term for the dies punches and holders found on press brake equipment.

Work piece the general term for the sheet metal part being bent.

A our angle is 45 degrees and our material thickness mt is 0 250 in.

The following form will help you calculate how much tonnage is needed to punch round holes through a given thickness of metal.

Die edge radius in.

The formula for calculating sheet metal bending allowance is please refer to the above picture.

A 1 degree tolerance on all bend angles.

The applied force stresses the metal beyond its yield strength causing the material to plastically deform but not to fail.

Od 90 complementary bend angle a dp b sine of bend angle 2 mt di b od 2 actual machine input depth dp di rp 0 03.

Continuing with the example introduced in figure 9 our required inside dimension is 0 250 in.

Tolerances general dimensioning and tolerances of bends and sheet metal.

Where ba is bend allowance.

Right angles are the most common feature found in most sheet metal fabrication.

Ba bend angle π 180 r k factor t eqn 1.